R-Tech expert Mike Gadsby talks MIG welding

You want a fast insight into MIG welding and the professional tips and tricks that help you get the most out of your MIG welding machine? Or perhaps you’re thinking of taking the plunge and trying MIG welding (or even welding, full stop) for the first time. What could be better than harnessing the expertise of a seasoned welding professional such as our technical sales administrator – and MIG welding expert – Mike Gadsby. Mike’s welded, managed a welding shop and supported welding machine sales for an impressive 33 years.

Before getting into the specifics of MIG welding aluminium, MIG welding settings or the best gas for MIG welding, we kicked off by asking Mike for his top MIG welding tips.

MIG welding tips

Personal protective equipment (PPE) really matters. That means a good quality welding mask, decent welding gloves and suitable clothing to protect you from arc burns. ‘Trust me,’ says Mike; ‘just a few minutes’ UV light exposure to unprotected skin during MIG welding can burn you as badly as really nasty sunburn.’

Welding without the correct welding mask will cause serious damage to your eyes called 'Arc-Eye' or welders flash: Never weld without a welding mask designed for electric arc welding.

Make sure your workpiece is dry and clean and free of rust or other oxides, which will spoil your weld. Don’t be afraid to do a dry run to get a feel for how the weld will work, and your movements while you do so. As Mike says, ‘Halfway through a critical MIG weld is not the time to find that you’ve got to change your position. Get comfortable, use two hands if it helps and maybe run some test beads on a piece of plate before you start the “real” job.’

Next up (especially important if you’re welding on vehicles), make sure there’s a suitable CO2 or dry powder fire-extinguisher nearby. Of course, your workplace Health & Safety, and good welding practice will mean fire precautions are in place, but it’s always worth double-checking.

‘Wire and gas-flow rate settings are critical,’ adds Mike, ‘so make sure these are right. The correct wire diameter must be matched the the current you will be using. The current (AMPS) will be dependant on the thicknes of material to be welding.

MIG welding wire types

According to Mike, mild steel typically demands A18 SG2 wire (although other wire specs are available for mild steel). Compare this to stainless steel where 316 or 308 wire is common (in the case of the latter, particularly when welding 304-grade stainless steel).

For aluminium, widely used wire specs are 4043 (5% Silicon content) or 5356 (5% Magnesium)

PRO TIP – If in doubt about correct wire specification, contact the wire manufacturer or give Mike and his R-Tech colleagues a call on 01452 733933

This leads nicely into MIG welding settings. Here are Mike’s top tips:

MIG welding settings

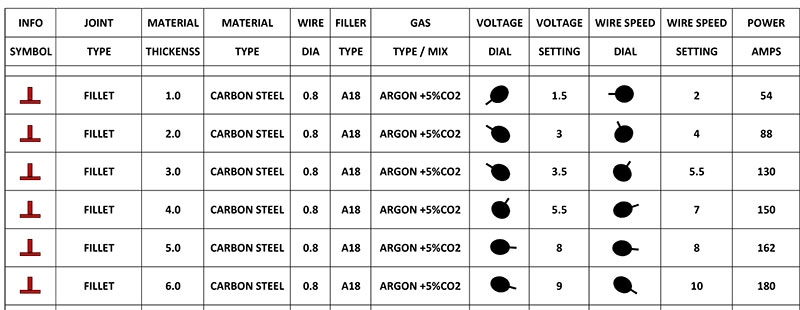

- Make sure you set the correct wire speed for the welding power (current or amperage). Below is chart showing Fillet Weld settings for our MIG180 on 0.8mm wire

See the full MIG180 welding chart here

See the full MIG250 welding chart here

- With experience, learn to ‘tune’ the wire feed by listening to the sound of the weld. In DIP transfer mode a sound a bit like frying bacon should be heard.

- Correct welding angle is 75 - 80 degrees with a pushing direction.

- Work within wire operating limits. For instance, 25A/mm is a good general guide for welding mild steel.

- Type of gas and gas-flow rate really matter.

What is the gas-flow rate on a MIG welder?

As a guide, around 12-14 lpm (litres per min), this can be set on the gauge on gas regualtor, for finer control we recommend using a gas flow meter, this can save gas from over use (too higher flow rate).

As with so much in life, the gas-flow rate for MIG isn’t an exact science and you must consider several variables. These include the following:

- Diameter of the MIG torch gas shroud.

- The type of weld.

- External factors such as draughts.

‘Don’t be shy about reading (or re-reading) the welding machine manufacturer’s operating instructions,’ says Mike, ‘or give us a call. Between us, there really isn’t much we haven’t already seen or heard.’

MIG welding techniques

With your settings established, it’s time to show off your MIG welding techniques. What does Mike have to say about this?

‘If you’re a professional welder, these will already be second nature to you. Please bear with me because a lot of new welders will be reading this and these tips will be helpful for novices or someone moving to MIG welding from stick welding or oxyfuel welding.’

From my MIG welding experience, the things to aim for include these:

- Being able to run a nice consistent bead.

- Using both hands if needed.

- Planning your weld before you strike an arc.

- Positioning yourself to see the weld clearly.

- Setting your shade for optimum visibility and eye protection.

- Prepping your workpiece thoroughly before welding – including cleaning and de-rusting if needed.

Mike continues: ‘You’ll know your MIG welding technique is progressing when you can successfully do trickier MIG welds (such as welding vertically up) right first time, every time. Practice various welding positions, get a feel for the effect of dialling in different wire-feed and power and practise your technique relentlessly.’

EXPERT PRO TIP – How should I MIG weld? Forehand vs. backhand welding? When MIG welding do you push or pull? The most usual way to MIG weld – and the way you’ll do most of your MIG welding – is to push the MIG torch in the direction of the weld – the ‘forehand’ method. Pushing directs the arc force away from the weld puddle, so forehand welding gives shallow penetration and a flat, wide, smooth-surfaced join. On the other hand, with the much rarer ‘backhand’ method (aka ‘pull welding’ or the ‘trailing technique’, you drag the MIG torch in a similar way to stick welding to give a narrower, deep-penetration weld that’s higher in the middle of the joint.

What does Mike consider the most challenging test of MIG welding technique? ‘It’s probably the inverted tee-weld,’ he explains. ‘When you can do those consistently, you know your technique is coming along well.’

With your MIG technique honed with ‘practice, practice and more practice’, you’re in a great position to demonstrate the advantages of MIG welding.

Advantages of MIG welding

Based on long experience as a welding expert, Mike’s top five advantages of MIG welding are as follows:

- Speed.

- Ease of use.

- Cost-effectiveness.

- Versatility.

- The fact that MIG welding requires less skill compared to, say TIG welding. Practice is key, but if you’re a less-experienced welder you should initially be able to weld better with MIG, than other welding techniques.

For a comprehensive write-up on the advantages and disadvantages of MIG Welding, view our dedicated article here.

Over the years, whether managing multi-machine welding shops or supporting R-Tech customers over the phone, Mike’s gained considerable practical MIG experience on different materials. So what are his thoughts on MIG welding stainless steel, aluminium and cast iron?

MIG welding stainless steel

‘At risk of repeating myself,’ he says, ‘make sure you choose the correct wire grade for the stainless steel. PRO TIP – Charts are available, consumables manufacturers can help, or we can advise you.’

What gas to use for MIG welding stainless steel?

Mike emphasises the correct choice of gas for stainless steel (‘normally argon (Ar)’) as well as the importance of a clean environment free of anything that could contaminate the weld.

‘Even having mild steel around can lead to contamination due to the chromium (Cr) and nickel (Ni) in stainless steel.’

PRO TIP – make sure grinding or cutting disks used on ferrous materials are never used for stainless. The contamination will ruin your hard work.’

MIG welding aluminium

‘It’s horrible stuff,’ says Mike, with a smile, ‘but we’ve got to work with aluminium – or “aluminum” in North America – so the correct approach is vital:’

- Again, wire feed is critical. Consider using a spool gun or a suitable Teflon liner and correctly profiled feeder rollers. The feed rollers for aluminium have special U-shaped grips all the way round so there’s less likelihood of deforming the wire profile and getting feed problems.

- Understand aluminium’s limitations – its high thermal conductivity and propensity to melt with excessive power – and weld accordingly. And the particular challenge of welding thin aluminium, say, with a thickness of less than 2mm.

MIG welding cast iron

‘You can’t MIG weld cast iron,’ says Mike, ‘although “MIG Brazing” may be possible.’ Faced with this material, the recommended action is to seek an alternative welding method, such as TIG welding or manual metal arc welding (MMA) off a TIG or MIG welding machine.

What kind of gas do you use for MIG welding?

Last but not least, what’s the best gas for MIG welding? ‘What gas is used for MIG and TIG welding?’ is one of the questions we’re asked most often.

Mike is quick to remind us that for MIG welding, argon, or argon mixed with another gas, is the norm for MIG welding. Here are some guidelines based on different materials:

- Thin mild steel: argon + 5% CO2 mix.

- Thicker-gauge steel: Using higher power, a lower argon percentage and around 15–20% CO2.

- Stainless steel: pure argon.

- Aluminium: pure argon.

Conclusions

Ask Mike Gadsby to sum up MIG welding and his message comes down to its versatility, cost-effectiveness, speed and relative ease of use for less-experienced welders.

‘It’s relatively easy to learn, compared with, say, TIG welding, and setting up for MIG welding is remarkably straightforward. In the hands of professionals, MIG is an amazingly powerful tool. And for beginners, it’s a rewarding and achievable skill.’

This makes MIG welding popular for a wide range of applications ranging from large-scale industrial welding to hobby welding in a garage or garden shed. Either way, correct preparation, the right protective kit, and the usual welding safety precautions are essential.’

Are you a MIG welding professional with a question for the R-Tech team, or a DIYer who fancies trying MIG welding for the first time?

Either way, the R-Tech MIG welding guide, demonstration videos and advice over the phone or by email are at your disposal. Give Mike and his colleagues a call on 01452 733933 – they’d love to talk MIG welding with you.