New R-Tech Plasma Cutter

Introducing the all new P51D 50 Amp Plasma Cutter

We at R-Tech Welding Equipment are proud to showcase our all new P51D 50-Amp Plasma Cutter

This new advanced plasma cutting machine takes the solid foundation of our highly popular P50HF model and elevates it to new heights.

The P51D is equipped with all new programs and settings, providing enhanced precision and efficiency designed to offer outstanding performance and versatility, making it the perfect choice for both professional welders and DIY enthusiasts alike.

So what's new?

Back Striking Start

https://www.r-techwelding.co.uk/newssystem/wp-content/uploads/2025/02/0219-13.mov#t=1,9

Back Striking Start:

The P51D is equipped with a new range of IPT60 Torches that features a Back Striking Start.

Unlike our previous models, which utilized a high-frequency (HF) start, this plasma cutter is designed around the Back Striking method.

While HF starts are beneficial for many cutting applications, there are specific situations where a back striking start is more advantageous.

With this new design, it is now easier than ever to cut through surfaces that previously required cleaning before using an HF machine such as painted or even rusty surfaces.

Additionally with this new feature, you can now effortlessly cut through tricky surfaces, such as mesh.

Gouging Function

https://www.r-techwelding.co.uk/newssystem/wp-content/uploads/2025/02/02191.mov

Gouging Function:

The all-new gouging feature allows you to remove metal from a workpiece without cutting the material into separate pieces.

This setting is particularly useful for eliminating unwanted metal, such as old welds that need to be removed before re-welding or resurfacing.

In this process, the arc generated by the plasma forms between the torch and the workpiece, melting the surface metal while preventing the arc from penetrating to the base of the material.

Setting up for Gouging

To set the Machine to gouge, simply fit the gouging consumables to your IPT60 Torch, select gouge mode on the right hand side of the display, set your amps and air pressure, and you're ready to gouge.

CNC Function

https://www.r-techwelding.co.uk/newssystem/wp-content/uploads/2025/02/0219.mov

CNC Function:

Before introducing this new machine, we manufactured two separate plasma cutting machines: the P50HF, a 50-amp handheld plasma cutter, and the P50CNC CNC plasma cutter.

While both machines performed admirably, we recognized the need for a versatile solution that would eliminate the necessity for customers to purchase two different machines whilst keeping the same performance and reliability that our customers have come to expect from our plasma cutters.

With this new model, we have eliminated the high-frequency (HF) start feature and developed a machine capable of both handheld plasma cutting and CNC operations.

Thanks to the all-new back striking start, you can now cut materials both freehand and via a CNC system.

You might be thinking, "That's great, but I'll still need two separate sets of consumables if I want to use this with my CNC setup." However, with the all-new P51D IPT60 type torches, we have designed the consumables to be cross-compatible between both the handheld torch and the machine torch.

Setting up the machine for CNC

To prepare the machine for use with your CNC system, simply select the CNC setting on the left side of the machine. Connect either your IPT60 torch or the IPT60 machine-type torch and then attach your CNC system via the input on the rear of the Machine and the machine is setup.

2T & 4T Touch Control

https://www.r-techwelding.co.uk/newssystem/wp-content/uploads/2025/02/0219-22.mov

The new 4T setting offers convenience and control, making it ideal for longer or more intricate cuts.

Unlike the traditional 2T mode, where you must continuously hold the trigger to maintain the arc, the 4T mode allows you to press the trigger once to start the arc and then release it, keeping the plasma arc active without the need to hold the trigger.

This hands-free operation makes it much easier to work on extended projects or detailed cuts, especially when you need to cut or manage longer continuous cuts.

Cutting Edge Cutting Capacity

https://www.r-techwelding.co.uk/newssystem/wp-content/uploads/2025/02/0220.mp4

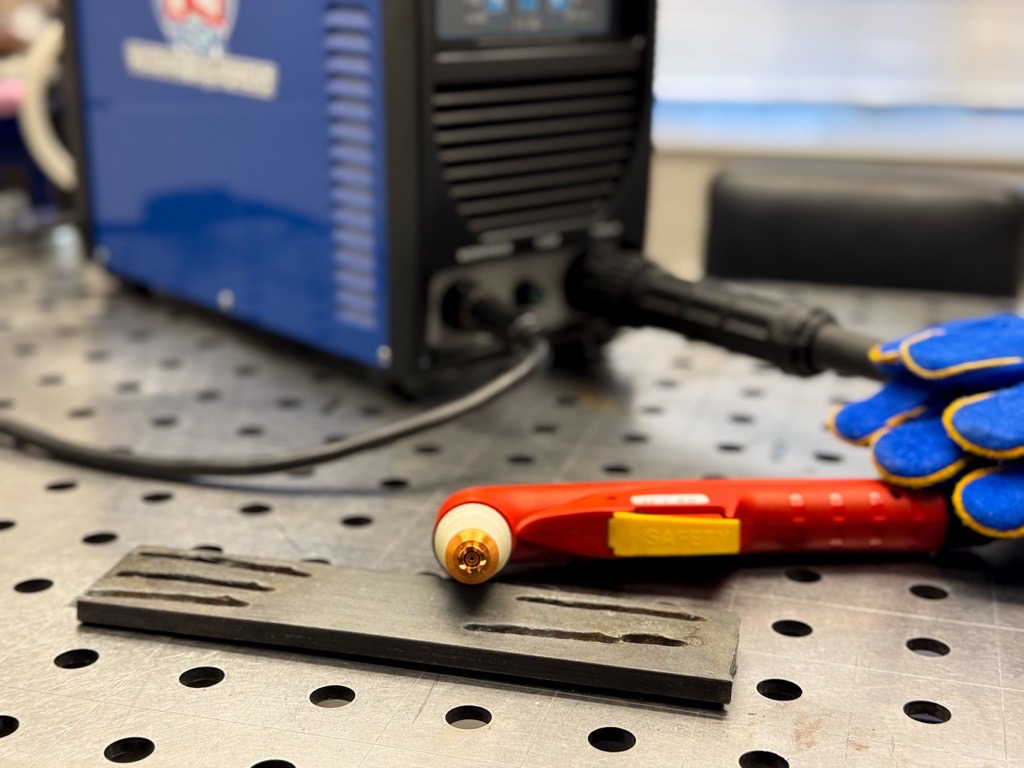

The R-Tech P51D Plasma Cutter boasts an impressive cutting capacity, offering a clean cut capability of up to 18mm and a severance cut capacity of 24mm.

This plasma cutter consistently delivers smooth and precise cuts across a variety of materials, including mild steel, stainless steel, and aluminum.

Whether you're working on industrial projects or DIY tasks, the P51D’s ability to provide clean, sharp cuts ensures both efficiency and reliability.

Its combination of high-quality performance and user-friendly design makes the R-Tech P51D a top choice for anyone seeking exceptional cutting results!

Want to learn more?

Checkout our latest videos:

https://www.youtube.com/watch?v=IkdLPIlc70Mhttps://www.youtube.com/watch?v=xBiSTwDAWmchttps://www.youtube.com/watch?v=Pj-_Bg5nzn8&t=3shttps://www.youtube.com/watch?v=ab9NlBbaFbI

Facebook

Instagram

Youtube

Linkedin

Checkout our latest blog posts: